cant wait to see an on board video

Ad Widget

Collapse

Announcement

Collapse

No announcement yet.

X

-

One question, on that video it didn't look like anything was connected from the turbo to the intake, was it? If it wasn't connected, the only success I see so far is an expensive sound mod. Last edited by Psycho1; 04-15-2011, 11:39 AM.John,

Last edited by Psycho1; 04-15-2011, 11:39 AM.John,

'05 GSXR750, '86 FZX700 Fazer, wifes bike '02 R6

sigpic

Comment

-

It looks like a 'start it up to see if it runs' kinda deal.. no turbo connect yet...http://www.7thgeardesigns.com

http://www.lunchtimecigar.com

'90 Suzuki 750 Kat

"Shut up and drink your gin" - Fagin (Oliver Twist)

"But, as is the usual scenario with a Harley it was off-line when it crashed," Schwantz added dryly.

"You didn't hear what I meant to say" - my Son

Comment

-

hey guys, totally forgot about this thread. For about the past month been dealing with moving and all those issues that come with it, and job stuff as well. so basicly it got put on the back burner. hopefully this week i can get back on it if i get the time, which i hope to devote to it..... in that vid, nope the charge pipe wasn't connected... i was having it running so i can test the scavenger pump and the turbo itself (and to make sure those plugs ran right i put in), that frickin pump sure pushes some oil!!!!!!! turbo sounded good, and looked good... so all thats next really is to just finish the gas tank, run some gas lines..... and just some other odds and end... btw, sorry rob that ive been busy and havent been able to shoot ya a text, just did a little bit ago."even one weak point is a weak point, DON'T MAKE ANY!" ~me

2006 turboed kat

2004 marauder 800

Comment

-

hey guys, just wanted to pipe in with an update.... finally got back to normal and have been going ape...."crap" on this things... the fuel system is done minus welding the return fitting in the tank, all the wiring is done (minus just hooking up with wires for the boost gauge).. exhaust is pretty much done, need to just get a tip for it, plenum is all bolted up and done.... so i should have this thing pretty much buttoned up within the next few weeks hopefully!............... on another note, ive gotten a few pm's and stuff and others asking me about where to start and all that on doing there own turbo bike...... here's a VERY good site i came across that "those" should look at.. http://www.unclebobsturbos.com/newbie.html ........ talk to ya guys later...

here's some pictures of the bike.

first we will start off with the boost gauge. Just a nice clean mount right in my vision... good enough.

Now here's the exhaust....

eh, somethings not right...

MUCH better...

i mean its not THAT low, I MIGHT be able to still drag a knee..

k all kidding aside....

just need a tip now.

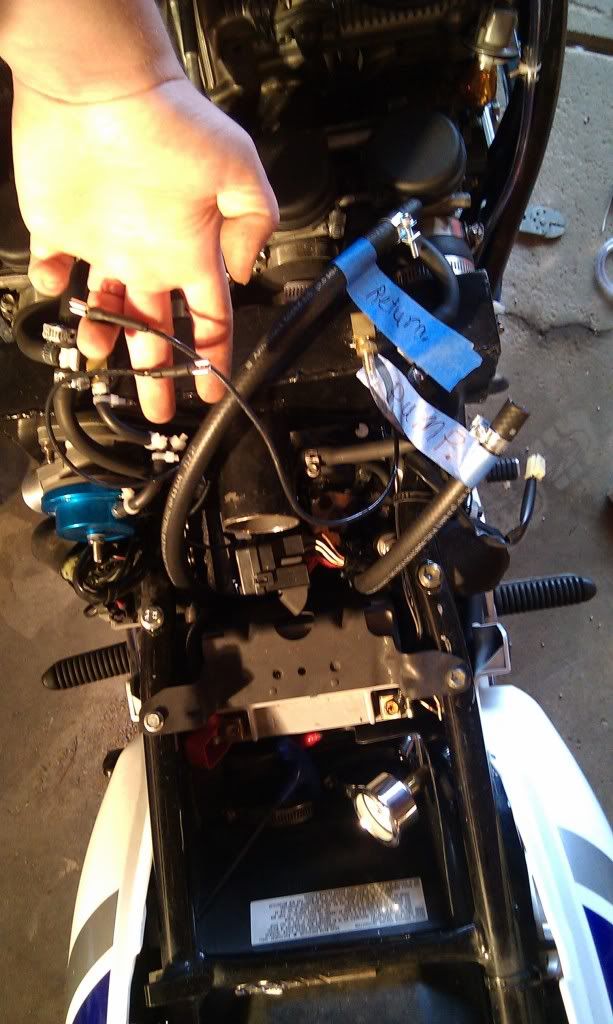

here's under the seat

in my hand im holding the wiring for the fuel pump, then you have the feed and return for the tank, the regulator is mounted way down yonder..

You can see in this one where the fuel press. gauge is. Its pretty much only there for tuning, so it doesn't matter if i see it while riding or not.

and here's another write up i came across as well

Bowl pressure

If pressure in venturi of carbs is raising due to boost, so should the pressure in bowl raise. Because if pressure in bowls is lower as it is in venturi, no fuel can be taken into the engine.

In my experience dynamic boost is absolutely nessecary, and it's best to give each connection on the carbs it's own spot on the tube going to the plenum: not in the plenum itself as there is to much pulsing. Make sure they are "angelcut" and in the middle of the airstream. (also known as pitot tubes)

On the GSXR1100 model 92 with the 40mm carbs you need to fasten the rubber T’s for instance with steel wire to prevent leakage and pressure drop.

Membrane pressure (CV carbs only)

Pressure above slidemembrane is not needed: it got it’s signal/pressure through the hole in the slide. Don’t enlarge the holes because the slides go up too fast and cause stuttering. (beware of dynojet kit modifications: larger holes and softer springs are a real pain in the butt for the midrange!)

Pressure below the membrane is needed. On the GSXR1100 model 92 with the 40mm carbs you have a seperate “venting” system with external hoses. Those are not suitable to pressurize. I removed that system, plugged the holes and drilled holes from the bellmouth towards under the diafram. When you drill you cross a not used hole. You have to plug that up also to prevent leakage and pressure drop. So it is made like the earlier models: the 36 and 38 mm CV carbs do not have this system.

Fuel pressure

The pressure of the fuel going to the bowls should be higher than the pressure in the bowl. If not, not any fuel is flowing into the carbs causing starvation as soon as boost starts to build.

Therefore you need a pump capable of making enough pressure to overcome boost + 2-3 psi at sufficient amount of fuel. The standard membrane pump on some carb bikes is definitely not up to the job: don’t even try it. An automotive EFI pump coming out of a car with the same amount of horsepower you are aiming for should work allright.

If you don’t use a regulator: you will have the maximum pressure on the bowls the pump can handle, and that will be around 90 psi and the end of your carbs.

A regulator is used (I use a malpassi and highly recommend it) to give the carbs a 2-3 psi above boost, so difference in pressure between pump and carbs is always the same independent of boost. Make sure you use a bypass type, not a deadend type as it is less accurate. If you can get away with 5 psi on the carbs without leaking, you can use static pressure and don’t need to modify the malpassi. It you have trouble with it, as I have, you need to shorten the spring in the malpassi a bit to achieve 2-3 psi. I also needed a bigger 8mm return line to be less restrictive. Than you definately need the dynamic pressure to prevent starvation under boost!

Jetting+tuning

Don’t make holes in the slides bigger, or use soft dynojet springs! They make things worse in the midrange area.

If you have your carbs and fuelsupply correctly setup: you don’t need to make big adjustments to needles and jets. Mine is actually on 125 mainjets (stock!) functioning just fine at 11.5:1 A/F

Don’t get an A/F any leaner then 12:1 A/F when you use some serious boost. You will burn up some pistons/valves. 11.5:1 is safe imho.

Use an A/F meter to see what’s going on. Looking at plugs is not saying too much, because if their getting hotter then normal on a turbocharged motorcycle they are white anyway.

Symptoms of lean and rich while driving can sometimes be very similar so in doubt always consult the A/F on a dyno!

Because of the lowered fuellevel it is nessecary to give more fuel for the idle, in my case 8 complete turns out for the mixture screws.

Extra tips:

Place a fuelfilter between pump and regulator. Not before pump because you restrict too much, and not after regulator because you messing with pressure which is critical on a carb/turbo setup. Make sure the fuelfilter can hold the pressure!

The return line of the regulator should be as less restrictive as possible: inside minimum 6mm returning into TOP of tank, not below fuellevel in tank. Otherwise fuel pressure cannot go as low as 2-3 psi. Don’t ever (I mean ever!) bend this line because fuel pressure can reach scary levels damaging your carbs seriously!!!!

Mount a fuelpressure gauge direcly next to the boost gauge so you can easy troubleshoot. Remove later if you want to.

Remove filter in your petcock, or better mount a less restrictive petcock without filter. Pingel makes these, but I machined a custom one with build in fuelreturn to the top of the tank so you don’t have to weld in a separate fitting in the tank

If it’s a vacuum operated petcock make sure you use the bypass mode: otherwise on boost the petcock will shut! This is a nice one, as you easily overlook it. On some models the petcock is really restricted in bypass mode so you have to modify that in some way.

If carbs overflow: put in new needles and valves. Make sure fuellevel is not too high: pressurized bowls have a slightly higher fuellevel so you maybe have to adjust it a few milimeters.

On very high horsepowerlevels there can’t flow enough fuel past the needles. Put in thinner/sharper dynojetneedles to solve this. Typical symptom is a sharp leaning out around peak torque, were you need the most fuel every stroke. This makes it harder to get the midrange ok.

At higher boost you can press out the choke plungers! This causes unwanted rich situations and stalling at closing the throttle. Put in stronger springs to solve.

Disclaimer

This info is true for my bike and my application. Some of this info is also true on other bikes/carbs but you have to check yourself. If it doesn’t work or you burn your engine up: I don’t accept any claims. If you crash due to an exploding engine: I’m really sorry and I will send flowers to your family but I am not responsible!

Good luck!Last edited by mstngsrule68; 04-25-2011, 04:50 AM."even one weak point is a weak point, DON'T MAKE ANY!" ~me

2006 turboed kat

2004 marauder 800

Comment

-

curious, why didn't you flip the turbo around and route the exhaust pipe as close to the stock setup as you could get? like to this guy

'04 Katana 1200 - B12 swap, Holeshot Stage 2 jet kit, 2 bros carbon fiber slip on cut down, 5 deg timing advance, Bandit 1200 rear wheel/180 tire w/ modified swingarm.

Comment

-

Originally posted by rob845 View Postcurious, why didn't you flip the turbo around and route the exhaust pipe as close to the stock setup as you could get? like to this guy

http://www.100-biker.co.uk/forums/sh...ad.php?t=40378

2 reasons..............

1. I wanted to be different, as you said before "like this guy"

2. There was some reason that i couldn't.... OH, the wastegate would be inside the oil filter. *sorry just remembered as writing*"even one weak point is a weak point, DON'T MAKE ANY!" ~me

2006 turboed kat

2004 marauder 800

Comment

-

Looks good! I'm subscribed"It's better to fail in originality than succeed in imitation."-Herman Melville

Chrisgraphic designer | drummer2002 Katana 600Check out my band Decadence @ Reverb Nation: http://www.reverbnation.com/#!/decadenceband

Comment

-

thanks, appreciate it..... well finally after spending ALL day, the exhaust is done(minus just putting a little wrap on it), got the tip today. Frickin another 20bucks there. Got some gasket material and cut out a gasket for the oil drain flange. Got ALL the wiring done finally, what a P.I.T.A. THAT was. The boost gauge finally dryed/cured so that got installed and wired(by the way, all this wiring isn't just take a butt connector and crimp it, its all soldered and heat shrink tubing). Gas tank will be done tomorrow as well. Well im sure im forgetting something after spending all day doing it, but oh well... I don't think i could ever complain about this project, yes its had its major up's and down's but overall, like anything that had some good pre-planning and a good idea.. This has come together pretty smoothly.... k now im rammbling, im done. time for rest.

So I have a question, has anyone noticed my relays/fuse's?

oh and here's a picture of the gauge, sorry I has in a hurry and didn't have a chance to snap a picture of it installed.

Last edited by mstngsrule68; 04-25-2011, 11:15 PM."even one weak point is a weak point, DON'T MAKE ANY!" ~me

Last edited by mstngsrule68; 04-25-2011, 11:15 PM."even one weak point is a weak point, DON'T MAKE ANY!" ~me

2006 turboed kat

2004 marauder 800

Comment

-

no problem man, tryin to do my best at posting everything up.

Well here's an update, the.....tank....is.....finally.....DONE. Woot!

here's a quick picture i snapped last night, i threw some paint on today. I just need to quick mount the fuel pump back on and then its going on.... i'll snap a couple more photo's tonight of it after the paint is finished drying and its put together.

here's the return on the tank.

as well as here's a picture of the completed exhaust, i still have some header wrap left over. So we'll see if i throw it on there or not, im sure i eventually will.

"even one weak point is a weak point, DON'T MAKE ANY!" ~me

"even one weak point is a weak point, DON'T MAKE ANY!" ~me

2006 turboed kat

2004 marauder 800

Comment

-

well finally got to the point that i can say............. THAT FRICKING RIDE IS AMAZING!.... i got a vid. from the helmet cam. but sadly i get home and realise i forgot it, so ill post that up tomorrow my bad.... but anyways, it pulls AMAZING.... not ONE single hiccup in it."even one weak point is a weak point, DON'T MAKE ANY!" ~me

2006 turboed kat

2004 marauder 800

Comment

great thread man! Please keep us posted.

great thread man! Please keep us posted.

Comment