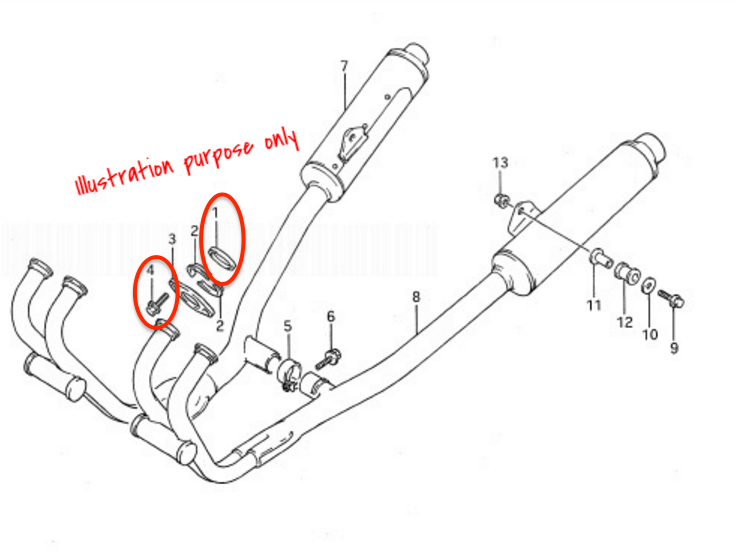

Hi, I am the new owner of a 1989 Katana 750 and it has some exhaust leaks. When I got it, it had an exhaust leak on one cylinder because the header pipe was broken off, so last night a friend and myself took the exhaust off and welded it up, and then put it back together with new gaskets. It was all fine last night, but when I started it this morning it now is leaking exhaust from all four cylinders. The only thing that I can think of is that we installed the little flanges (part number 2 in the image above) backwards so that they are not actually pressing the header against the gasket. Currently the part that flares out on the flange is against the header (with the rest of the flange sitting inside the clamp plate [part #3]), but I am wondering if it is supposed to be the other way around with the flared out part against the clamp plate and the rest of the flange pressing against the header. This seems to make the most sense to me, although I have looked in the service manual available for download (thanks btw!) and it says nothing about these flanges. I only got the idea by looking at the above image in frustration after trying to fix the leak this morning. Any input would be appreciated.

Comment