Degrees of Difficulty

* Easy,suitable for

novice with little

experience

** Fairly easy, suitable

for beginner with

some experience

*** Fairly difficult,

suitable for competent

DIY mechanic

**** Difficult, suitable for

experienced DIY

mechanic

***** Very Difficult,

suitable for expert DIY

or professional

Degree of Difficulty - ***

Ok, I wanted the Bandit chain adjuster design. IMO it's way better then the Katana. The problem is the Bandit chain adjuster has a different ID for the rear axle.

Here's what I did.

IMG]http://i209.photobucket.com/albums/bb212/arsenic13_bucket/8c90_2.jpg[/IMG]

I started with a set of stock Katana adjusters (I sell parts I had like 3 sets, but your adjusters will work), either pre or post will work, I used post. A stock set of Bandit adjusters I got on ebay. Here's what you need:

(there are 2 of both p/n 61410-08F00 and p/n 61421-45000, but in the picture I just had room for 1)

that's right when you get the stud out of the Katana chain adjusters, there in a hole in there that will work for the M8 x 1.25 Bandit screws. To get the studs out of the Katana chain adjusters, cut through the welds with a cutting wheel. If you look at the stud, it's welded on. Cut through that and then use a punch and hammer to just punch the stud out. Then use a bench grinder, or a grinding wheel on a die grinder to grind the face of the chain adjuster smooth. The stud in the Katana adjusters are also M8 x 1.25. Now with the studs out of the Katana adjusters it's really easy. Take the M8 x 1.25 nuts (I used the nuts that were welded into the Bandit adjusters, but any M8 x 1.25 nut should work) and JB weld them inside of the Katana adjusters, the JB weld is just a temporary hold, then nuts will be tack welded in place before they are used. I threaded the nuts onto a bolt, again M8 x 1.25, and pulled the bolt up to JB the nuts. With the nuts JB Welded on the inside of the Katana adjusters, they will be welded before use, you can now use all the Bandit parts with the Katana adjusters.

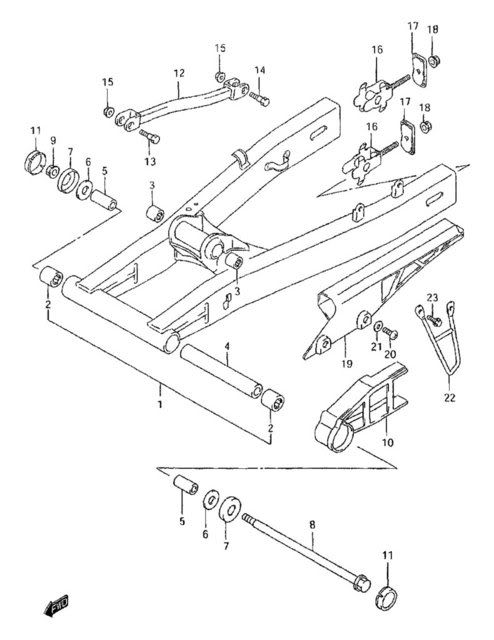

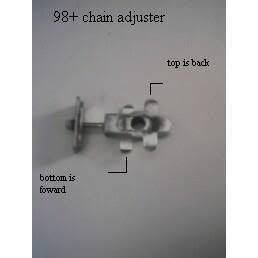

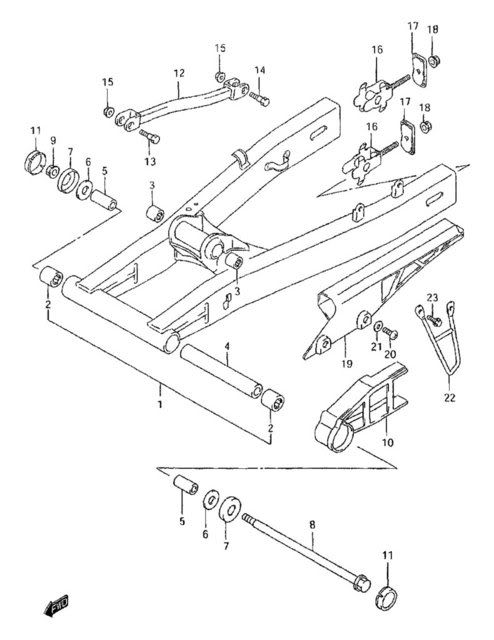

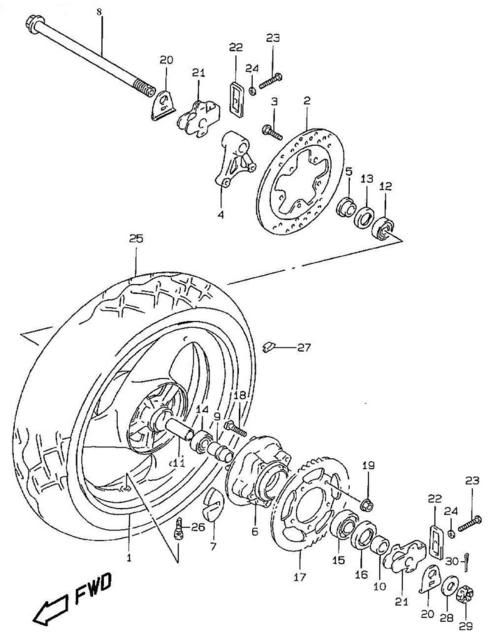

This is a 98+ Katana microfiche, item #16 is the adjuster. Item # 18 is a M8 x 1.25 nut that will work.

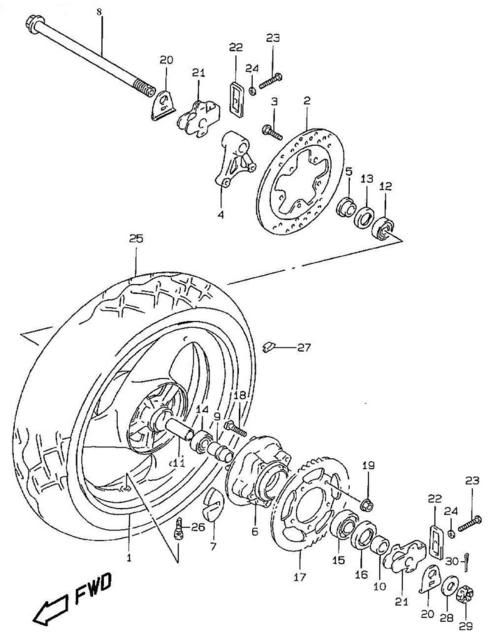

This is a Bandit microfiche. Item # 23 are the screws, item # 24 are the washers, and item # 22 are the plates.

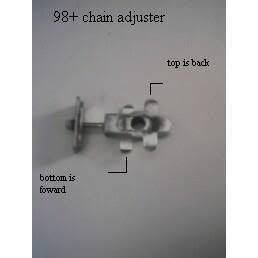

The difference between pre and post Katana adjusters:

98+ Katana adjuster and pre 98 (pictured) measurement = 1 5/16" - 1.3125" (33.3375mm)

Bandit adjuster measurement = 1 5/8" - 1.625" (41.275 mm)

If you have any questions, let me know.

* Easy,suitable for

novice with little

experience

** Fairly easy, suitable

for beginner with

some experience

*** Fairly difficult,

suitable for competent

DIY mechanic

**** Difficult, suitable for

experienced DIY

mechanic

***** Very Difficult,

suitable for expert DIY

or professional

Degree of Difficulty - ***

Ok, I wanted the Bandit chain adjuster design. IMO it's way better then the Katana. The problem is the Bandit chain adjuster has a different ID for the rear axle.

Here's what I did.

IMG]http://i209.photobucket.com/albums/bb212/arsenic13_bucket/8c90_2.jpg[/IMG]

I started with a set of stock Katana adjusters (I sell parts I had like 3 sets, but your adjusters will work), either pre or post will work, I used post. A stock set of Bandit adjusters I got on ebay. Here's what you need:

(there are 2 of both p/n 61410-08F00 and p/n 61421-45000, but in the picture I just had room for 1)

that's right when you get the stud out of the Katana chain adjusters, there in a hole in there that will work for the M8 x 1.25 Bandit screws. To get the studs out of the Katana chain adjusters, cut through the welds with a cutting wheel. If you look at the stud, it's welded on. Cut through that and then use a punch and hammer to just punch the stud out. Then use a bench grinder, or a grinding wheel on a die grinder to grind the face of the chain adjuster smooth. The stud in the Katana adjusters are also M8 x 1.25. Now with the studs out of the Katana adjusters it's really easy. Take the M8 x 1.25 nuts (I used the nuts that were welded into the Bandit adjusters, but any M8 x 1.25 nut should work) and JB weld them inside of the Katana adjusters, the JB weld is just a temporary hold, then nuts will be tack welded in place before they are used. I threaded the nuts onto a bolt, again M8 x 1.25, and pulled the bolt up to JB the nuts. With the nuts JB Welded on the inside of the Katana adjusters, they will be welded before use, you can now use all the Bandit parts with the Katana adjusters.

This is a 98+ Katana microfiche, item #16 is the adjuster. Item # 18 is a M8 x 1.25 nut that will work.

This is a Bandit microfiche. Item # 23 are the screws, item # 24 are the washers, and item # 22 are the plates.

The difference between pre and post Katana adjusters:

98+ Katana adjuster and pre 98 (pictured) measurement = 1 5/16" - 1.3125" (33.3375mm)

Bandit adjuster measurement = 1 5/8" - 1.625" (41.275 mm)

If you have any questions, let me know.

Comment