Sweet, 8 cylinder mode did the trick! The tach in MS is now within ~120RPM of whatever the Kat tach says. Revs much smoother and now will go above 6000rpm. Todays plan is to take it for a ride, come back and resync the throttles, then maybe go for another short ride with the laptop in the backpack. Of course its the 4th so the emissions place and DMV are closed but I might be able to get a temp tag. If not then tuning will have to wait and I'll have to stick to parking lots again. I hate arizona sometimes. It's so hot out, and just to **** me off we are the ONLY state in the US to require emissions testing for bikes.

Ad Widget

Collapse

Announcement

Collapse

No announcement yet.

X

-

-

Mini update, tomorrow I need to get a USB extension cable so the MS can reach the laptop while its in a backpack. The tune is still really rough, especially after leaning it out for emissions. It'll pull strong up to 7000RPM where it starts coughing and choking, but now the throttle response is pretty bad. Still isnt bad for never having the tuning software running while riding.

Comment

-

Alright, got a nice long usb cable and took a ride with the laptop. Rode around for a good few miles while datalogging, and got some good info out of it. I gunned it hard and got it up to about 9500 rpm but it was coughing the whole time above 7500. Logs show it peaked at 21:1 AFR!! That explains quite a bit.

In the logging software theres a mode to analyze the VE tables vs the actual logged AFR and correct as needed. I ran that mode just now and it made some massive corrections. Of course, somehow its raining right now (even though it was over 105* an hour ago..) so I cant play with it anymore today. Looking forward to tomorrow though.

Comment

-

Few updates just to let you guys know I'm still here.

I got my license after passing the MSF course yesterday, so now I can try it out on freeways. The bike is still an epic ***** to start. Cold starts and hot starts need completely different settings and I'm having trouble getting them to work correctly. Without a CTS I have to manually put it in "first start mode" and it adds more fuel. This works fine for a true cold start but it doesnt like when the engine is warm but not hot. I'm getting closer, though I still keep jumper cables in the backpack just in case...

You'd see much more progress but its so damn hot here (and humid now too) that I just can't bring myself to work on any of my projects during the day. Stupid Arizona. I can't wait for winter.

Anyway, apart from hard starting I have zero complaints about the system. I'll keep updating as I progress.

Edit: I forgot to mention what first start mode actually is. Its a "carburatorism" of sorts, like a choke. You turn the ignition on, and pump the throttle 3 times before hitting the start button and MS will multiply the cranking fuel by an adjustable percentage. This could be done away with by using an oil temp sensor wired into the coolant temp input on MS.Last edited by TheSteve; 07-26-2008, 05:41 PM.

Comment

-

Alright, chapter 3 is here: Tuning!

***NOTE ANY REFERENCES TO HEI, 8 CYL MODE, 2 CYL MODE ARE OBSOLETE. RUN THE MS IN 4 CYL MODE WITH THE REVISED TACH INPUT CIRCUIT ABOVE***

I finally got everything running well enough to take her on the freeway. Still wont ****ing start on its own half the time, but

thats another issue for another day. Prior to today I wasnt about to get autotune or anything like that working correctly. Looking

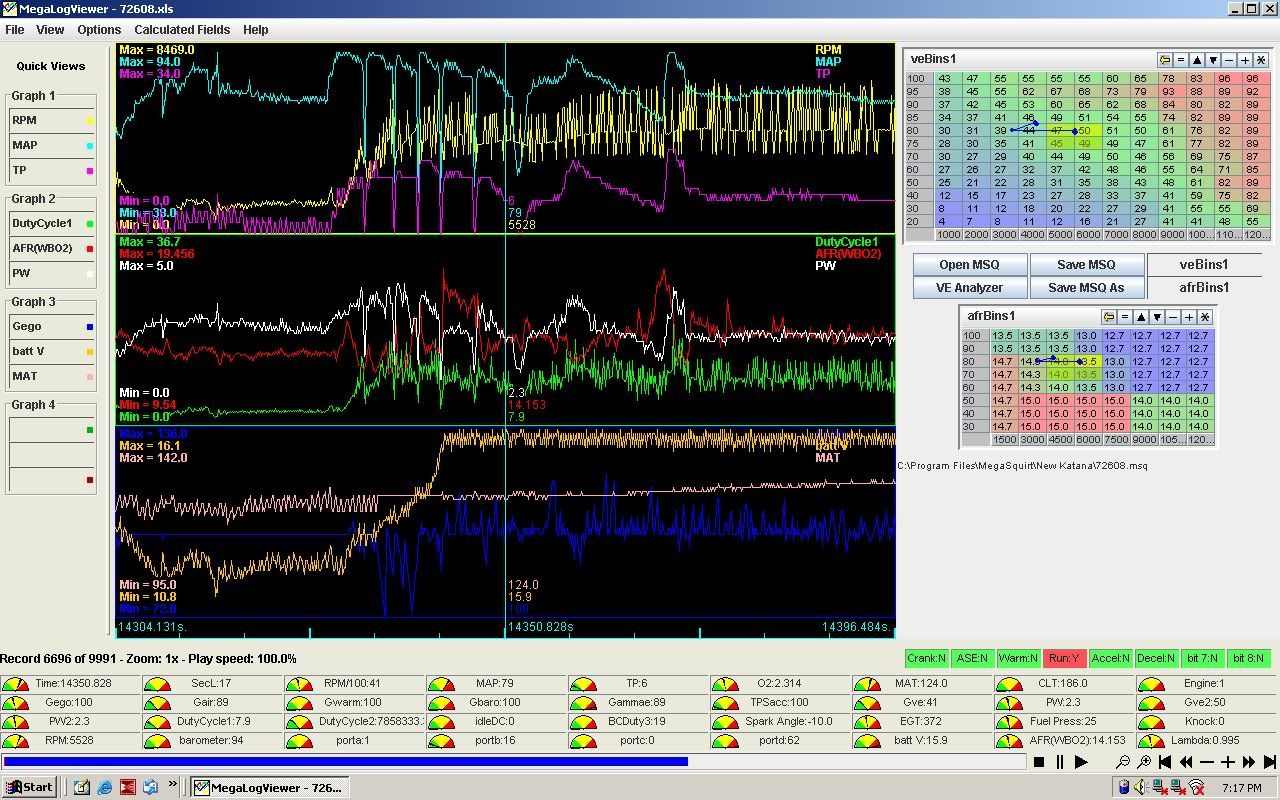

at the logs I was getting pretty bad tach spikes above 2000rpm. Heres a screenshot from an old log showing this:

Note how you can see the rpm changing rapidly here (over 2000rpm/sec). Clearly this isnt really happening, as the bike wouldnt be

rideable. On the megasquirt-n-spark extra forums (alternative firmware that I'm using) I found a schematic to increase the

accuracy of the HEI tach input. ***Had to remove a diode, resistor, and jumper and connect a new resistor elsewhere.*** Now the tach

is perfectly clean. I have no idea why the signal was so dirty, but either way it confused the hell out of MS at higher RPM. Here is

the "fixed" signal of a different ride:

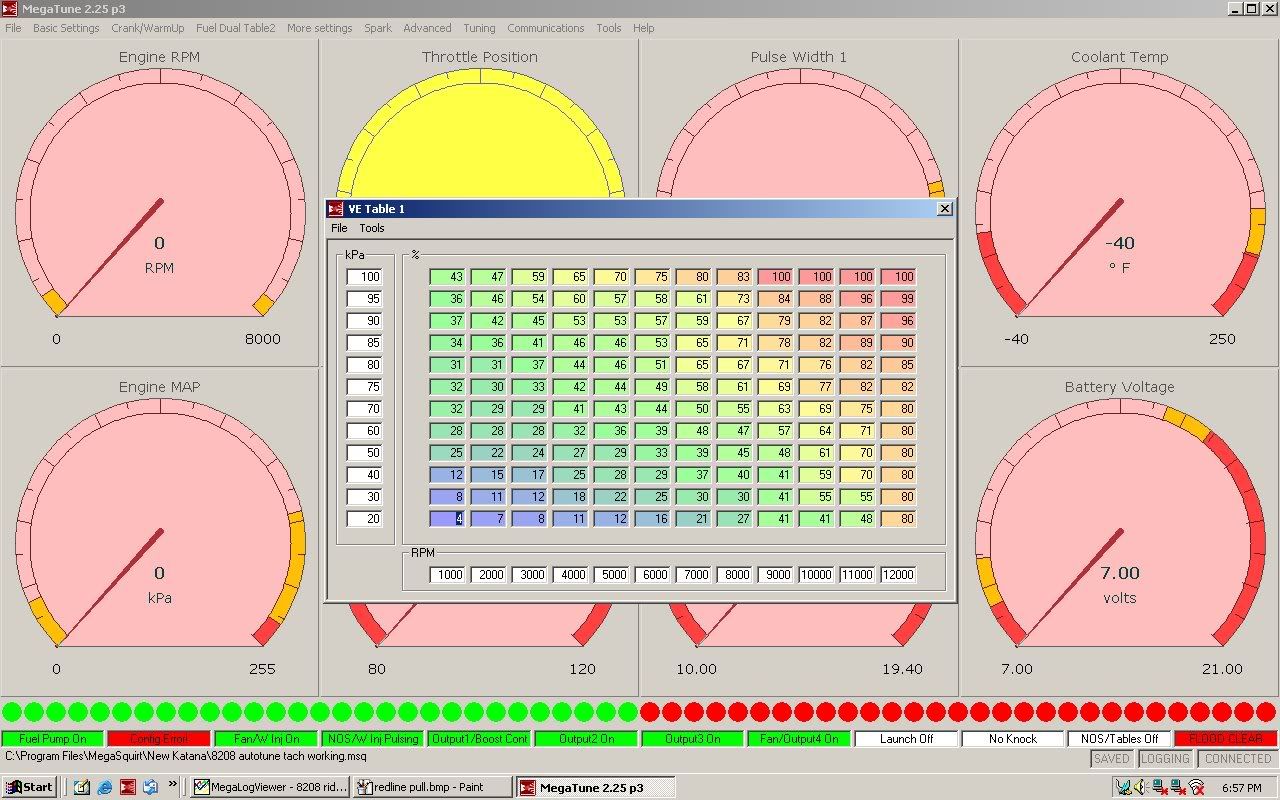

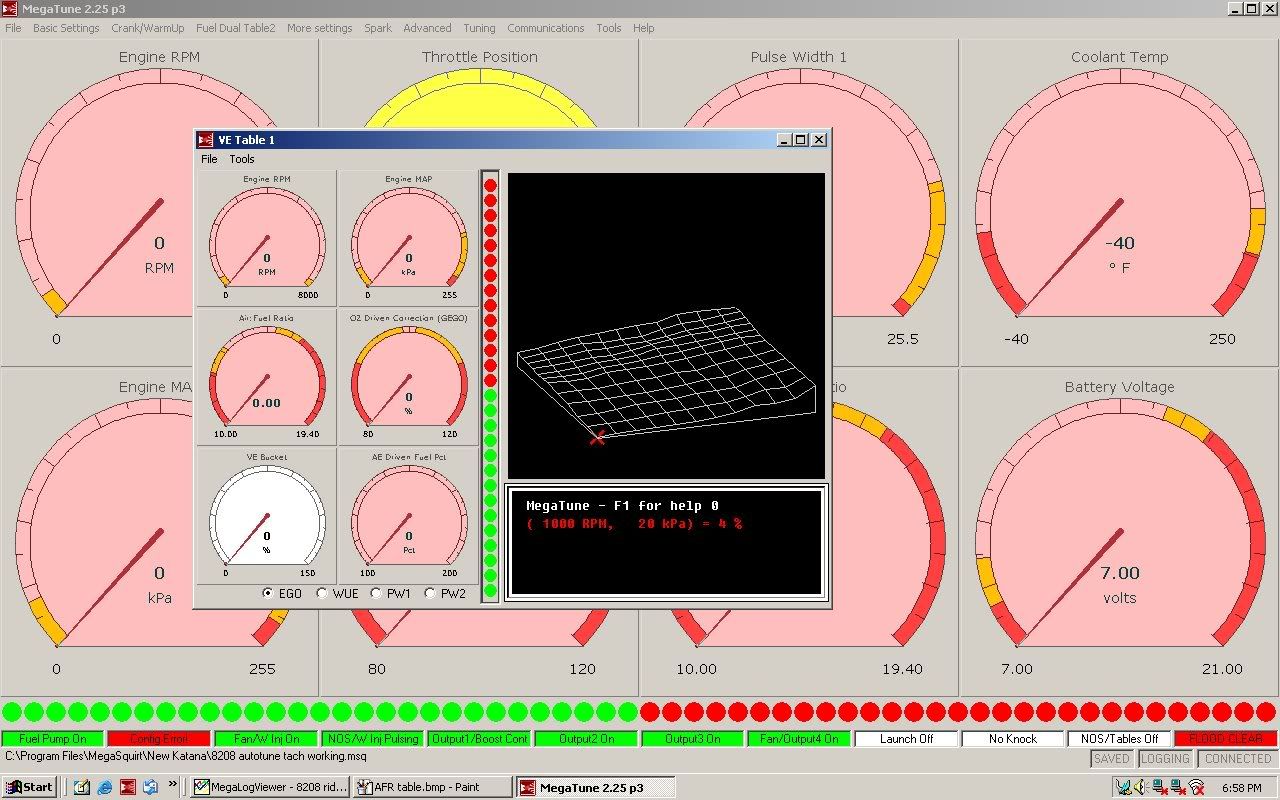

So heres what we're working with:

The actual tuning of the bikes AFR is done here at the VE table. The numbers are percentages representing how much of the

air/gas mixture actually fills the cylinders. So a 600cc engine at 50% VE is only getting 300ccs of air/gas in the motor in one

cycle. The vertical axis is the manifold absolute pressure (MAP) reading and shows engine vacuum in KPA. 100 KPA is about equal

to atmospheric air pressure at sea level. The horizontal axis is the RPM. So when you open the throttle the engine vacuum drops

to zero (or MAP rises to 100, same thing).

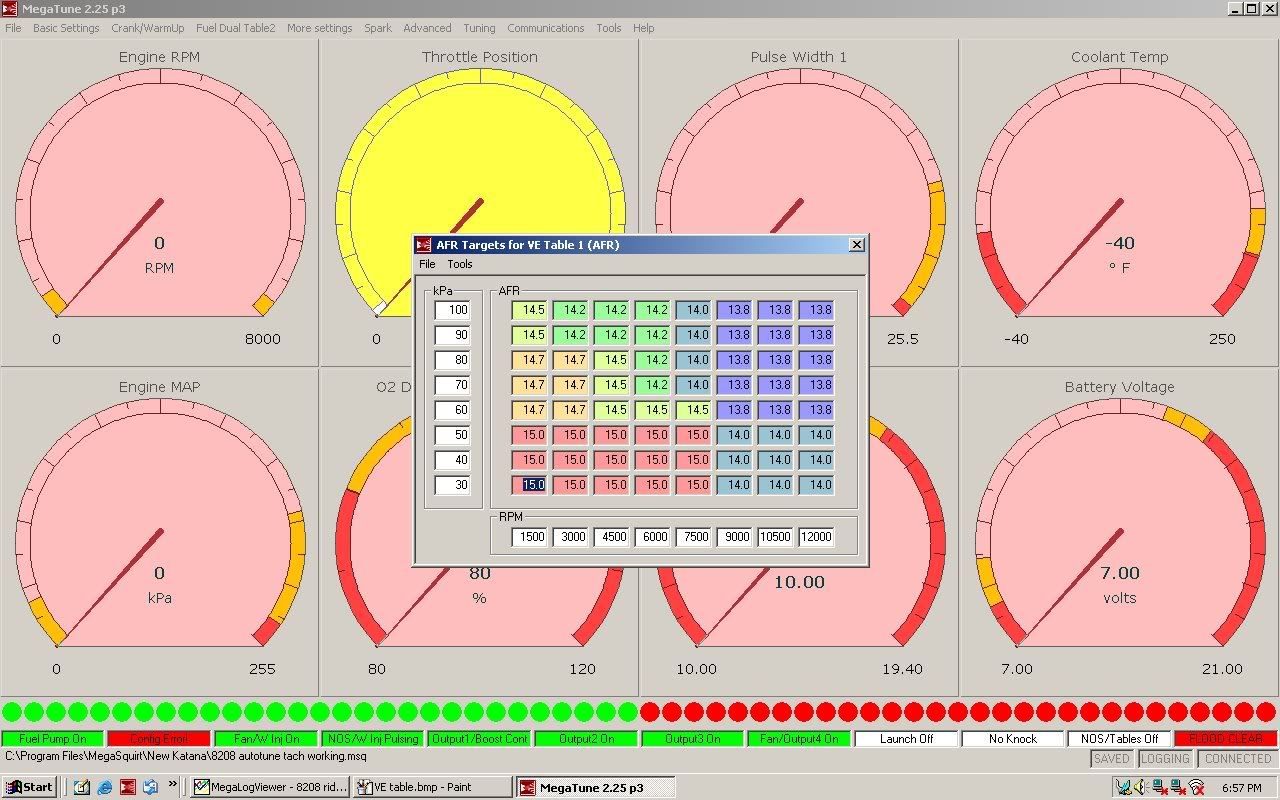

This is the Target AFR table. You tell MS what AFR numbers you want and it tries to hit them by adjusting injection pulsewidths.

This is ONLY useful if you have a wideband. Narrowbands only say "richer than 14.7" or "leaner than 14.7" and they cannot tell the

MS any more than that. With a narrowband system you aim to get fast oscilations between too rich and too lean on the O2

sensor. If youre constantly going between the two a few times a second, your mixture is pretty much dead on. However running

14.7 afr at redline is likely going to melt a piston or two. So no narrowbands for WOT tuning.

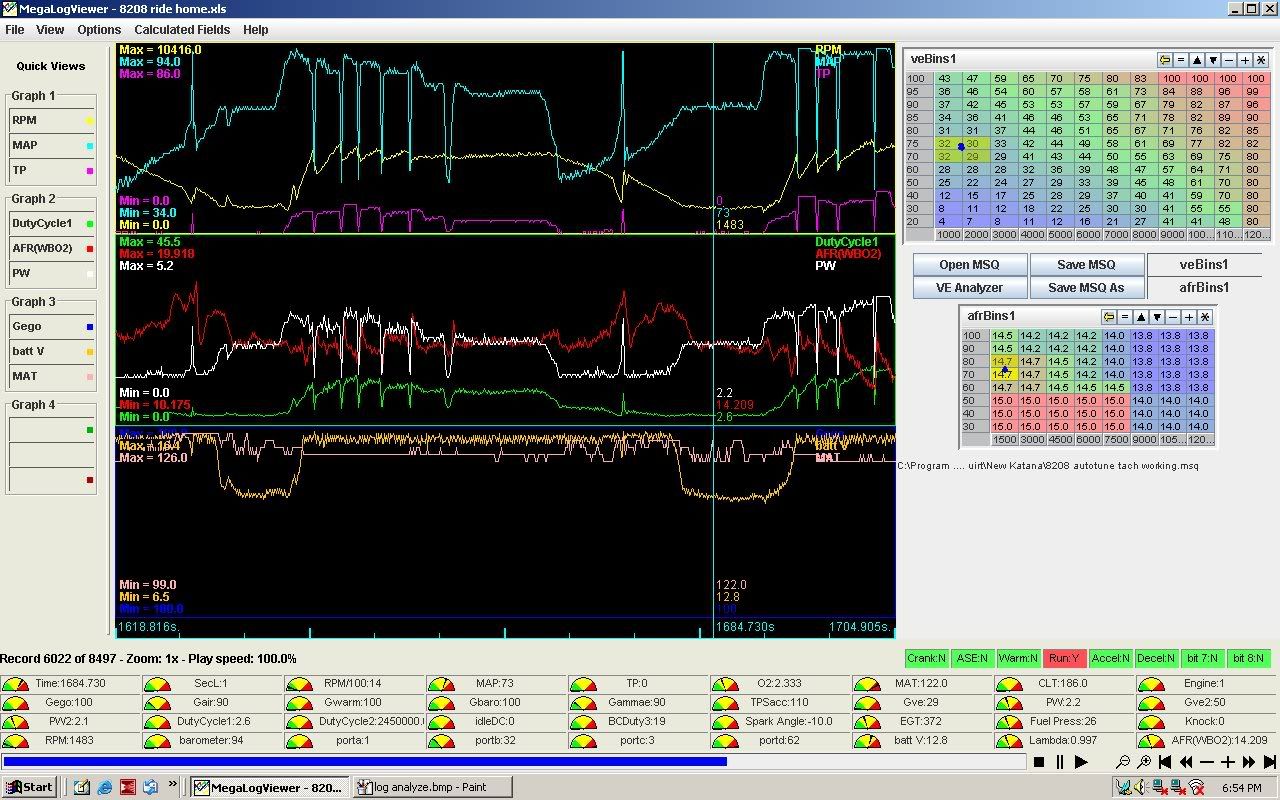

This is the MegaLogViewer. It graphs data that Megatune logs while riding, dyno testing, etc. In the main screen you see the 3

graphs showing whatever data you select. To the right you see the VE table for this log. Below the VE table is the AFR target

table again.

Clicking the VE Analyzer button brings you here, where the program checks every record in the log (over 8000 on this 15 minute

ride) and compares the recorded AFR to the target AFR. If they dont match, a new value for the VE table is suggested based on

the "on target" sections of the logs and some math I dont care to explain. It actually works pretty well. This will only be the third

time I've run the analyzer and even after two the bike is perfectly rideable. The only hard part came from the fact that the built in

calculator in megatune didnt like the high redline of the Kat, so I had to draw the initial table from a blind guess.

Thats about it, actually. Tuning an MS system like this is pretty much datalog (ride), analyze tables, burn to the ECU, repeat until

satisfied. With my other projects tuning is a little bit easier. In megatune theres a feature called Autotune, and it runs in real time

instead of going off logs. It's also a little safer to use in that you can see if you go crazily lean since the laptop is sitting on the

passenger seat. You might be able to get it to work with the laptop in the backpack as well, but I didn't want to try it without

being able to see the screen. Heres what it looks like if you want to try that route instead.

Now I just have to get it to start every time. I need an oil temp sensor, but I'm not sure how to do it. I'm thinking about maybe

just gluing one to the outside of the oil pan as I'd rather not drill and tap the aluminum pan. I could also see if I could attach it to

the hot side of the oil cooler but there might be some lag time until it warms up with hot oil being pumped through. Sorry for all

the huge pics, in low res you probably wouldnt be able to see the details. Let me know if you have any questions.Last edited by TheSteve; 08-22-2008, 06:07 PM.

Comment

-

Forgot to mention, if anyone wants a copy of the entire log file to look at just let me know and I'll post it up. The logging software is available for free.

Comment

-

Is there a way to run those logs off of a carb, or is it just for an MS system? Here's another question, any ideah what the difference would be for putting the injectors on a Post Kat as opposed to a Pre? Or should I just leave it alone and find a Gixxer to play with.

Comment

-

The engine is 99% the same on a post, so I would think fitting the throttle bodies would be about the same. The only forseable difference is the throttle cable. And I think you'd have more room to work with under the seat for placing the MS box.

Theres sort of a way to log with carbs. With the wideband, it comes with software to log directly onto a computer (no MS required). The hard part would be assigning a tach and throttle position to the log as well. Just logging the AFR over time would be easy, but pretty pointless since you dont know whats happening at that exact moment in time. A better idea might be to buy the LC-1 package that comes with an AFR gauge. You could mount the gauge to the handlebars and just try to remember where the rich and lean spots are.

The hard part really isnt getting an AFR log, its in the other two signals. While the post does have a TPS from the factory it might be hard to tie into the logging software that comes with the wideband. Same for the tach.

Check that out. It looks like the TPS and RPM should be able to be adapted to the logging software pretty easily. I'd advise shopping around a little bit, you might be able to find a better price.

Comment

-

Steve, I know your fuel rail doesn't leak, but is there a standard NPT tap and union that could use there? I have no idea what the ID on the GSXR fuel rail is.

Also, the oil pressure dummy light sensor should be a good place to tap into for a temp sensor. All you'd need is some kind of T fitting and put the dummy light sensor on one end and the temp sensor on the other.

Good idea, dumb idea??

Comment

-

Holy ****, thats perfect! I'm even running one of those on my other car, I can't believe I forgot about it.Originally posted by ATOMonkey View PostAlso, the oil pressure dummy light sensor should be a good place to tap into for a temp sensor. All you'd need is some kind of T fitting and put the dummy light sensor on one end and the temp sensor on the other.

Good idea, dumb idea??

As for a fitting on the fuel rail, I'm not quite sure. The ID is very small. Probably about a quarter inch or less.The OD is a more reasonable size for an adapter but youd have to grind it perfectly smooth for a metal adapter to seal correctly.

Comment

-

Standard NPT tap sizes are .250 NPT and .190 (or #10) NPT.

You could also drill and tap the ID out to whatever size is next up on the chart, like a 3/8 or 5/16 NPT. Maybe something to do in the down time. I'm just a little leary of heater hose as an HP fuel line, for safety sake.

Comment

Comment