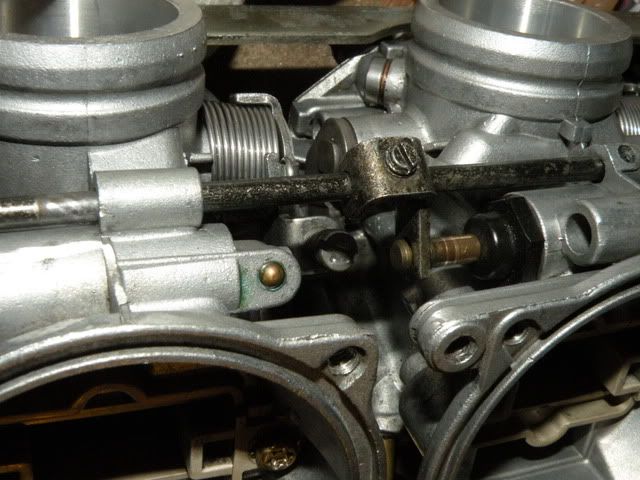

Today I attempted to make a manometer for synchronizing my carbs. I followed the idea described here: http://faq.ninja250.org/wiki/How_do_...-bottle_method

Here's a bill of parts for my homemade manometer:

Subtotal:

2*1.16+2.98=$5.30+tax

Tip: don't use plastic bottles!

Or you'll get this when you start up the engine:

Instant squash! It squished enough that some drops of water got into the lines to the bike, which freaked me out bigtime!!

BTW that's water and food coloring.

BTW that's water and food coloring.

Tip: you might not want to use 10W40 oil with 1/4"x0.170" (OD/ID respectively) tubing.

It doesn't seem to flow very well. Then again, seeing how much vacuum there actually is, maybe it would be fine. It just took a LOT of effort sucking on the hose to get the oil from one bottle to the other and gravity wasn't doing much to equalize the two.

Tip: put the stoppers in the freezer for an hour while your cordless drill battery charges; makes it a bit easier to drill the holes

Tip: I tried using a smaller size bit and working up to the 1/4" for the hole, and then I tried just using the 1/4" right away... either way produced similar results.

Tip: Dip the end of the vinyl tubing into some oil before stuffing it into the stopper; makes it go in much easier

Tip: Cut the lengths of tubing which go up to the carbs to be longer than 3'. 3' only barely gets from the ground to the carbs... it IS long enough, but only barely. Give yourself the extra length. 10' of tubing from Home Depot should be enough, but it only costs a few cents more (why IDK) for 20', so it can't hurt to get 20'.

Tip: Home Depot employees have no clue where their rubber stoppers are located... go to the Hardware section... the aisle with the nuts and bolts. Look for the drawers with small specialty hardware like hitch pins and lock washers... they're in there (bottom right drawer at my Home Depot).

I didn't have any glass bottles so I'm busy dealing with the contents of some Mike's Hard lemonade bottles right now for the cause. Will report in tomorrow if it works. Ordinarily I'd be enjoying beer, but these bottles are clear, and you need to be able to see the liquid in your manometer! Orangina would probably work too.

Will report in tomorrow if it works. Ordinarily I'd be enjoying beer, but these bottles are clear, and you need to be able to see the liquid in your manometer! Orangina would probably work too.

EDIT: UPDATE: The Mike's bottles worked great; see my update post below (about 4 down).

I checked the stoppers with one of the empties and the opening on the Mike's bottle is smaller than a plastic soda bottle... the 1" stoppers are too big, but I can probably stuff them in if I try hard enough. I would get smaller ones if you decide to use beer bottles. However, the smaller the stopper, the harder it is to drill the holes in them for the tubing, so keep that in mind!

EDIT: UPDATE: The stoppers worked fine in the Mike's bottles. A bit hard to squish in at first, but they were very snug. Could still probably get a smaller size though.

Here's a bill of parts for my homemade manometer:

- Two glass bottles (check your recycling bin) -- free

- Two rubber stoppers. Home Depot 1" x 25/32" Rubber Stopper $1.16 ea (these fit soda bottles but are too big for beer bottles... get a size or two smaller)

- 10'-20' vinyl tubing. Home Depot 1/4" x 0.170" x 20' Clear Vinyl Tubing $2.98

Subtotal:

2*1.16+2.98=$5.30+tax

Tip: don't use plastic bottles!

Or you'll get this when you start up the engine:

Instant squash! It squished enough that some drops of water got into the lines to the bike, which freaked me out bigtime!!

BTW that's water and food coloring.

BTW that's water and food coloring.Tip: you might not want to use 10W40 oil with 1/4"x0.170" (OD/ID respectively) tubing.

It doesn't seem to flow very well. Then again, seeing how much vacuum there actually is, maybe it would be fine. It just took a LOT of effort sucking on the hose to get the oil from one bottle to the other and gravity wasn't doing much to equalize the two.

Tip: put the stoppers in the freezer for an hour while your cordless drill battery charges; makes it a bit easier to drill the holes

Tip: I tried using a smaller size bit and working up to the 1/4" for the hole, and then I tried just using the 1/4" right away... either way produced similar results.

Tip: Dip the end of the vinyl tubing into some oil before stuffing it into the stopper; makes it go in much easier

Tip: Cut the lengths of tubing which go up to the carbs to be longer than 3'. 3' only barely gets from the ground to the carbs... it IS long enough, but only barely. Give yourself the extra length. 10' of tubing from Home Depot should be enough, but it only costs a few cents more (why IDK) for 20', so it can't hurt to get 20'.

Tip: Home Depot employees have no clue where their rubber stoppers are located... go to the Hardware section... the aisle with the nuts and bolts. Look for the drawers with small specialty hardware like hitch pins and lock washers... they're in there (bottom right drawer at my Home Depot).

I didn't have any glass bottles so I'm busy dealing with the contents of some Mike's Hard lemonade bottles right now for the cause.

Will report in tomorrow if it works. Ordinarily I'd be enjoying beer, but these bottles are clear, and you need to be able to see the liquid in your manometer! Orangina would probably work too.

Will report in tomorrow if it works. Ordinarily I'd be enjoying beer, but these bottles are clear, and you need to be able to see the liquid in your manometer! Orangina would probably work too.EDIT: UPDATE: The Mike's bottles worked great; see my update post below (about 4 down).

I checked the stoppers with one of the empties and the opening on the Mike's bottle is smaller than a plastic soda bottle... the 1" stoppers are too big, but I can probably stuff them in if I try hard enough. I would get smaller ones if you decide to use beer bottles. However, the smaller the stopper, the harder it is to drill the holes in them for the tubing, so keep that in mind!

EDIT: UPDATE: The stoppers worked fine in the Mike's bottles. A bit hard to squish in at first, but they were very snug. Could still probably get a smaller size though.

..

..

Comment